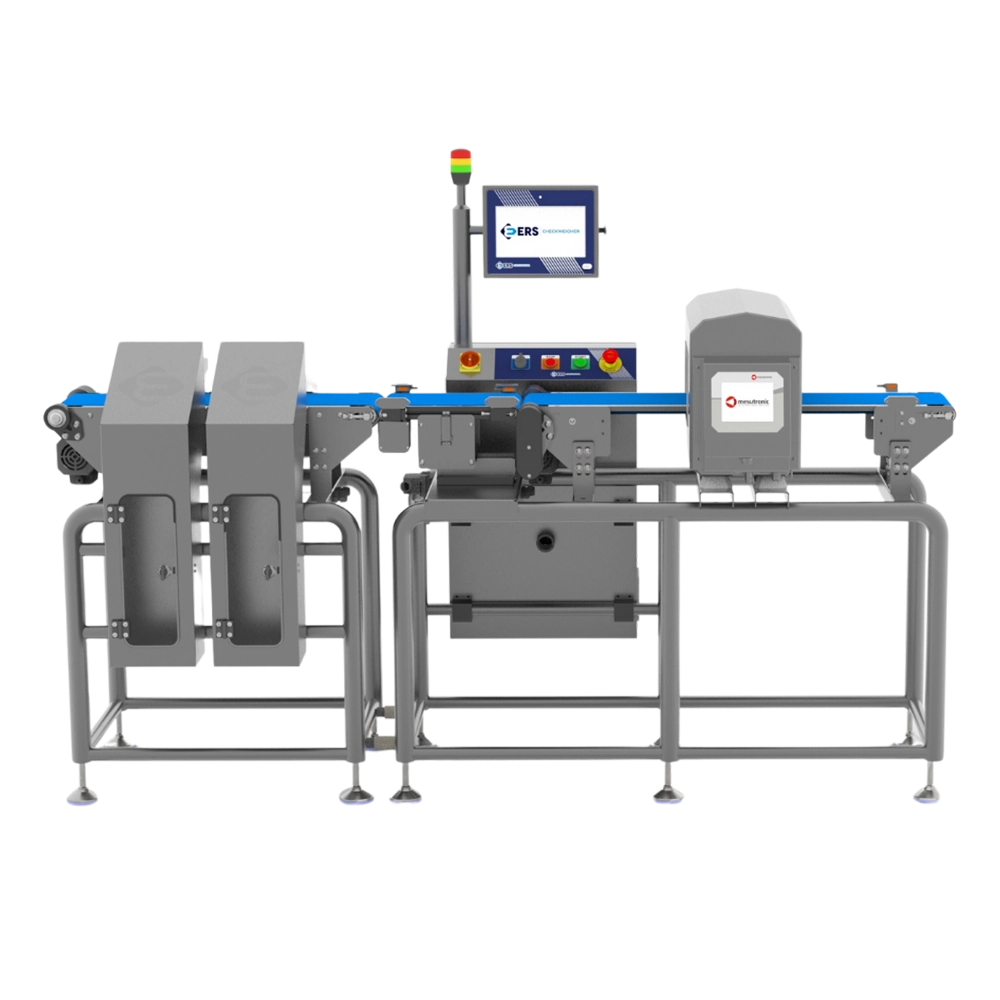

The combined system offers high precision and accuracy to ensure product safety and quality at the production line at maximum level. This system integrates the checkweigher and metal detector to precisely measure both the weight and metal contamination of the packageshe combined system offers high precision and accuracy to ensure product safety and quality at the production line at maximum level. This system integrates the checkweigher and metal detector to precisely measure both the weight and metal contamination of the packages. The high accuracy rate guarantees that each package complies with the standards and minimizes faulty product output.

The device’s sensors are designed to detect even the smallest deviations. As the packages pass through the production line, the device automatically scans for both weight and metal contaminationhe device’s sensors are designed to detect even the smallest deviations. As the packages pass through the production line, the device automatically scans for both weight and metal contamination.

Thanks to the sensitivity, small metal particles or weight deviations are detected immediately and faulty packages are automatically separated. This is particularly critical in ensuring quality and safety in food, pharmaceutical and precision product manufacturing.

The accuracy feature ensures that false positive or negative results are minimized. Operators can work faster and more efficiently on the production line by trusting the measurement results. The system records production data and allows quality control teams to analyzehe accuracy feature ensures that false positive or negative results are minimized. Operators can work faster and more efficiently on the production line by trusting the measurement results. The system records production data and allows quality control teams to analyze it. Thus, faulty products are detected quickly and the production process is optimized.

High precision and accuracy on busy production lines ensure that the workflow is uninterrupted and safe. Without the need for operator intervention, the device makes continuous accurate measurements and increases the efficiency of the production line. The waste rate is reduced and the product quality is constantly maintained.

As a result, the Combined System’s high precision and accuracy feature Decouples safety, quality and efficiency on the production line. Both the weight and metal contamination of each package are controlled precisely and accurately.s a result, the Combined System’s high precision and accuracy feature Decouples safety, quality and efficiency on the production line. Both the weigh

The combined system offers high precision and accuracy to ensure product safety and quality at the production line at maximum level. This system integrates the checkweigher and metal detector to precisely measure both the weight and metal contamination of the packageshe combined system offers high precision and accuracy to ensure product safety and quality at the production line at maximum level. This system integrates the checkweigher and metal detector to precisely measure both the weight and metal contamination of the packages. The high accuracy rate guarantees that each package complies with the standards and minimizes faulty product output.

The device’s sensors are designed to detect even the smallest deviations. As the packages pass through the production line, the device automatically scans for both weight and metal contaminationhe device’s sensors are designed to detect even the smallest deviations. As the packages pass through the production line, the device automatically scans for both weight and metal contamination.

Thanks to the sensitivity, small metal particles or weight deviations are detected immediately and faulty packages are automatically separated. This is particularly critical in ensuring quality and safety in food, pharmaceutical and precision product manufacturing.

The accuracy feature ensures that false positive or negative results are minimized. Operators can work faster and more efficiently on the production line by relying on the measurement results. The system records production data and allows quality control teams to perform analysis.he accuracy feature ensures that false positive or negative results are minimized. Operators can work faster and more efficiently on the production line by relying on the measurement results. The system records production data and allows quality control teams to perform analysis. Thus, faulty products are detected quickly and the production process is optimized.

High precision and accuracy on busy production lines ensure that the workflow is uninterrupted and safe. Without the need for operator intervention, the device makes continuous accurate measurements and increases the efficiency of the production line. The waste rate is reduced and the product quality is constantly maintained.

As a result, the Combined System’s high precision and accuracy feature Decouples safety, quality and efficiency on the production line. Both the weight and metal contamination of each package are controlled precisely and accurately.s a result, the Combined System’s high precision and accuracy feature Decouples safety, quality and efficiency on the production line. Both the weigh

The combined system offers easy and fast control on the production line with a user-friendly 10.2 inch color touch panel.he combined system offers easy and fast control on the production line with a user-friendly 10.2 inch color touch panel. This large screen visualizes all the functions of the checkweigher and metal detector; weight measurements, metal detection results, production statistics and system alerts can be followed clearly on the panel. The touch interface allows operators to operate the device quickly and intuitively.

The panel functions as the central control point of the production line. Operators can adjust the scanning sensitivity, manage automatic reset modes and control alarms. In this way, rapid detection and intervention of faulty products in the production line is provided.he panel functions as the central control point of the production line. Operators can adjust the scanning sensitivity, manage automatic reset modes and control alarms.

In this way, rapid detection and intervention of faulty products in the production line is provided. Colorful and graphical indicators on the panel make it easier to understand critical data and support fast decision-making.

The panel, which has been made durable through industrial design, is resistant to dust, moisture and impacts. The readability of the screen is high even in low light environments and operators can easily follow the production processhe panel, which has been made durable through industrial design, is resistant to dust, moisture and impacts. The readability of the screen is high even in low light environments and operators can easily follow the production process. Graphs and alerts show the situation on the production line instantly, helping operators to detect errors early.

The panel also works integrated with statistical data and reporting systems. Weight and metal scanning data can be viewed in real time, historical data can be analyzed and production performance can be optimizedhe panel also works integrated with statistical data and reporting systems. Weight and metal scanning data can be viewed in real time, historical data can be analyzed and production performance can be optimized. This feature makes the device not only a safety and weighing tool, but also a strategic tool for production management and quality control.

As a result, the 10.2-inch color touch panel is one of the most powerful features of the Combined System in terms of ease of use, data tracking and production control. Thanks to the panel, operators can manage the production line safely and quickly, and use all the functions of the device with maximum efficiency.s a result, the 10.2-inch color touch panel is one of the most powerful features of

Thanks to the integrated operation of the checkweigher and the metal detector, the weight and metal scanning data of each package are recorded and can be displayed in clear graphics. This allows operators and managers to easily analyze the performance on the production line.

Graphs and tables reveal trends and possible deviations in production processes. Information such as which shift metal contamination is seen more often, which product groups experience weight deviations, can be clearly seen.raphs and tables reveal trends and possible deviations in production processes. Information such as which shift metal contamination is seen more often, which product groups experience weight deviations, can be clearly seen. In this way, production planning and quality control processes are improved, faulty products are prevented and productivity is increased.

The data recording system stores historical scanning and weighing data, making long-term analysis possible. Production trends, device performance and deviations can be reported in detail. This not only saves costs but also prevents faulty products from entering the markethe data recording system stores historical scanning and weighing data, making long-term analysis possible. Production trends, device performance and deviations can be reported in detail. This not only saves costs but also prevents faulty products from entering the market. It helps to maintain quality standards by creating a reliable data source during audit processes.

Graphical data, provides great convenience for operators. When the scanning and weighing results are visualized instantly, faulty products are detected quickly and intervention can be made on the production line. This reduces waste and improves the efficiency of the production line ratesraphical data, provides great convenience for operators. When the scanning and weighing results are visualized instantly, faulty products are detected quickly and intervention can be made on the production line. This reduces waste and improves the efficiency of the production line rates. Additionally, statistical data supports quality control processes and provides guidance for error-free production.

As a result, the statistical data and graphs feature facilitates data tracking on the production line, prevents errors and increases operational efficiency. Thanks to the integrated operation of the checkweigher and the metal detector, both the weight and metal scanning processes can be analyzed in detail, and the production quality is constantly maintained.

Conveyor changeover allows for quick switching between different product types. For example, during the switch from small packaged products to large packages, the conveyor can be adjusted quickly and the device performs the necessary automatic calibrationonveyor changeover allows for quick switching between different product types. For example, during the switch from small packaged products to large packages, the conveyor can be adjusted quickly and the device ponveyor changeover allows for quick switching between different product types. For example, during the switch from small packaged products to large packages, the conveyor can be adjusted quickly and the device performs the necessary automatic calibration. This flexibility supports the efficient operation of the production line and prevents production from coming to a halt.

Conveyor replacement also provides a great advantage in maintenance and cleaning processes. The parts can be easily removed and cleaned, so that hygiene standards are maintained and production safety is ensured. The risk of operators making mistakes during conveyor changes decreases to a minimum and work safety increases.

During the conveyor change, the device optimizes the weight and metal scanning accuracy, ensuring that each product is scanned correctly. In this way, faulty product output is prevented on the production line and the waste rate is reduced.During the conveyor change, the device optimizes the weight and metal scanning accuracy, ensuring that each product is scanned correctly. In this way, faulty product output is prevented on the production line and the waste rate is reduced. Fast and safe conveyor change in busy production lines directly affects production efficiency.

As a result, easy conveyor changeover is a critical feature that increases the efficiency of the integrated checkweigher and metal detector system, lightens the workload of operators and supports hygiene and safety. In this way, different product types can be processed quickly and accurately, and the production line operates uninterruptedly and safely

Multi-language options allow operators to use the device in their own language, reducing training time and reducing the risk of misuse. Personnel working in different production facilities can display menus and warnings in their own language and manage all the functions of the system correctly.ulti-language options allow operators to use the device in their own language, reducing training time and reducing the risk of misuse. Personnel working in different production facilities can display menus and warnings in their own language and manage all the functions of the system correctly. This especially improves the quality and safety of international production lines.

Different language options allow operators to work faster and more efficiently during the production process. During metal scanning and weight measurements, the risk of incorrect adjustments or interventions is minimized because the operator can see warnings and instructions in his ownifferent language options allow operators to work faster and more efficiently during the production process. During metal scanning and weight measurements, the risk of incorrect adjustments or interventions is minimized because the operator can see warnings and instructions in his own language. This situation is of great importance in terms of maintaining operational efficiency, especially in intensive and fast production lines.

The device’s software is designed to make language changes quick and easy. Administrators can view the device’s menus and reports in the language they want, and thus quality control and inspection processes can be carried out in international standardsvice’s software is designed to make language changes quick and easy. Administrators can view the device’s menus and reports in the language they want, and thus quality control and inspection processes can be carried out in international standards. When production teams have the advantage of being able to use the device in different languages, the workflow becomes more organized.

Multi-language support also strengthens communication between teams. Operators who receive training in different languages can manage the device in their own language, increasing harmony within the team. This supports the safe and error-free operation of the production lineulti-language support also strengthens communication between teams. Operators who receive training in different languages can manage the device in their own language, increasing harmony within the team. This supports the safe and error-free operation of the production line. At the same time, it expands the scope of use of the device and allows it to be used smoothly in production facilities in different countries.

As a result, multiple language options provide operator-friendly use. Language support ensures that the device is used both safely and effectively and contributes to the smooth operation of the production line. It offers a critical advantage in terms of adapting production facilities to different standards and markets

The intelligent automatic reset feature ensures that the device always makes accurate and reliable measurements on the production line. The system automatically resets itself at specified intervals and eliminates any deviations that may occur in the sensors. In this way, false positive or negative results are prevented and an uninterrupted, safe process is provided on the production line.

The reset process occurs without the need for operator intervention. This relieves the workload of operators in busy production lines and guarantees the continuous correct operation of the device. Each weighing and metal check is done accurately and without deviation, minimizing the output of faulty productshe reset process occurs without the need for operator intervention. This relieves the workload of operators in busy production lines and guarantees the continuous correct operation of the device. Each weighing and metal check is done accurately and without deviation, minimizing the output of faulty products. At the same time, the production quality is constantly maintained.

The device’s software manages the reset process in an integrated manner with production data. The performance of the sensors is monitored and necessary corrections are applied automatically. This ensures that quality control teams have reliable data and allows them to analyze production trends accuratelyhe device’s software manages the reset process in an integrated manner with production data. The performance of the sensors is monitored and necessary corrections are applied automatically. This ensures that quality control teams have reliable data and allows them to analyze production trends accurately. It is possible to detect faulty products quickly and optimize production processes.

Intelligent automatic reset covers both the checkweigher and metal detector functions. The sensitivity and accuracy levels of both systems are maintained, ensuring that the production line always operates safely and efficiently. This feature reduces human errors and increases the reliability of the device.

As a result, intelligent automatic reset ensures high precision, safety and efficiency in the production line. The continuous accurate measurement of the device is guaranteed, the workload of the operators is reduced and error-free production processes are supported. This feature offers a critical advantage in terms of quality control and production efficiency.